Brahmapuram Waste to Energy Project

Brahmapuram Waste to Energy Project Gallery

Brahmapuram Waste to Energy Project

Background

An international competitive tender was published by Kochi Municipal Corporation through KITCO as transactional advisors in March 2014 for the treatment and disposal of unsegregated MSW at Brahmapuram. The proposed project was on a Public Private Partnership [PPP] basis and required the winning bidder to Design, Build, Finance, Operate and Transfer (DBOFT) the facility for 20 years. The corporation would be responsible to deliver 300 Metric Tonnes of Municipal Solid Waste to the facility on a daily basis. The power generated from MSW would be purchased by Kerala State Electricity Board (KSEB) under a secured power purchase agreement as part of the contract. Through a very comprehensive bidding and technical evaluation process, GJ Nature Care & Energy Pvt Ltd secured the contract in Q1 2016. The total capital expenditure, in excess of 300 Cr, for the project would be invested by the company and no government investment is involved in this project. The project is fully supported by the Corporation, State Government and the Government of India as a key priority for the city and as a benchmark for the rest of India. The power generated will be Green energy preventing significant amount of methane and CO2 generation from the existing MSW dumping site. This project will place Kochi in the world map for adopting proven scientific initiative for carbon reduction through sustainable MSW management solution.

Technology Summary

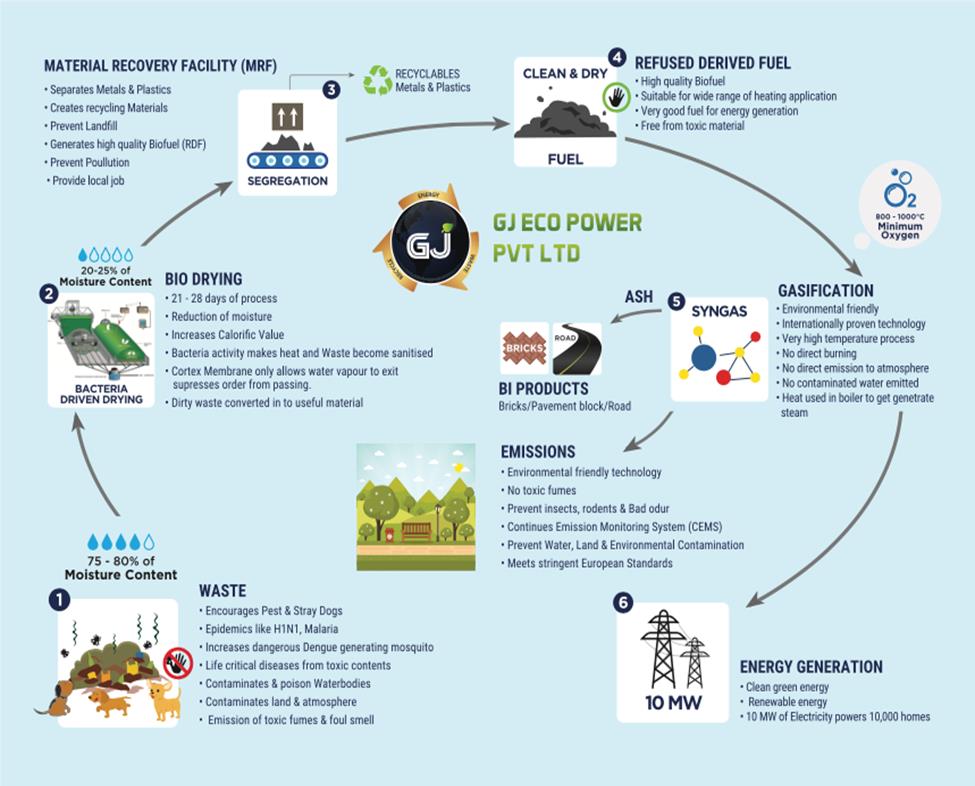

The MSW from Kochi possess several technical and practical challenges while converting to effective energy generation source. The higher moisture content, seasonal variations in waste profile and low calorific value are some of the key challenges. The detailed waste analysis from the source, day to day content profiling, calorific value testing, moisture content, inert material variation and the seasonal organic and moisture variation profile over the past 5 years provided the company with a statistical profile of Kochi‘s MSW. The technological solutions were carefully selected by our technical expert panel to ensure robust operations with efficiency.

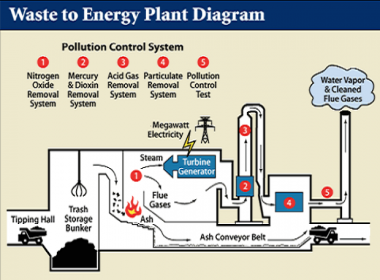

The unsegregated waste is verified and profiled before transferring to the collection bay and the MSW is initially treated through a proven state of the art German Bio Drying process for a period of over 20 days to remove the moisture from the organic materials and convert it to usable fuel. This technology uses minimal energy with effective drying through eco-friendly patented natural process. This technology is well proven globally as this process efficiently dries the entire organic mass including the internally trapped water molecules. The segregation is fully automated as the dried MSW will be easier to segregate with automated verification process followed by manual confirmation ensuring removal of chlorinated plastics, recyclable materials and inert materials from the Refused Derived Fuel (RDF). The RDF will be stored based on varying calorific values in different automated chambers prior to blending and feeding in the Gasification process. The controlled RDF from the blending process will be fed through the automated Gasifier to generate syngas which will be utilized as a fuel source in the Steam power generator.

Gasification is proven globally as a robust method in the MSW to Energy generation process when RDF is controlled adequately. Our British Gasifier is a new generation Gasifier with higher efficiency and operational robustness. The inbuilt emission treatment system is supported by world-class emission controls which fully comply with the much stringent EU emission and pollution control guidelines. The plant is designed to set world class emission standards in Kochi through this project. The emission levels from the plant will comfortably meet all Indian standards and exceed European requirements. The leachates and the ash residues from the process will be treated within the facility and no further land, air and water pollution will be induced from this plant. Each element of the technology and its providers were carefully selected to meet Kochi‘s unique MSW requirements by our experts. The project is technically and financially viable, making it an absolute stepping stone in India’s CO2 reduction effort through scientific waste management and green energy production. This sustainable MSW solution will enable the city of Kochi to match world class standard and this will prevent a large number of social and health concerns including stray dogs, food borne diseases, insect and rodent proliferation.

Benefits of Gasification technology over conventional methods

Gasification process is a proven and robust method of MSW to energy generation over the past 25 years across developed countries. Gasification offers a range of advantages over direct combustion of the fuel because it translates about 80% chemical energy in the waste fuel into chemical energy in the gas phase. Gasification is a thermal upgrading process in which the majority of the carbon in the solid fuel is converted into the gaseous form (syngas), leaving an inert residue (char or ash). The process involves the partial combustion of a portion of the fuel in the reactor with air, limited oxygen air or by reaction with steam. The energy content of the fuel is therefore transferred into the gas phase as chemical energy, which can be utilized to generate power and/or heat. The components in the syngas could also be used to produce chemical feed stocks.

Gasification process employs relatively high temperatures of 1000 - 1400°C with minimal oxygen. Syngas contains carbon monoxide, Hydrogen and smaller quantities of methane depending on the reactor type, as well as some of the unconverted reactants such as carbon dust, mineral ash, carbon dioxide and nitrogen. These need to be cleaned from the syngas prior to utilization in gasification process. A heavy duty moving floor feeds fuel into the heavy duty reciprocating step grate via a finitely controlled metering device. The grate gasifies the fuel to produce a volatile gas. These volatile gases are then combusted at above 850°C for more than two seconds to ensure complete combustion. Once the gasification and then secondary combustion process is completed the hot gas is exchanged via a fire tube steam boiler into 450°C steam, at a pressure of 41 Bar. This is then used to produce high efficiency electricity in a vacuum condensing turbine. Once the hot gases are released from the boiler at low temperature they go through a dust filtering treatment process which monitors flue gas emissions constantly and in doing so ensures compliance with the emission standards. A SCADA (Supervisory Control And Data Acquisition) system is employed to significantly enhance the plant control and maximize the performance. The plant will be designed to meet very stringent European environmental standards to set a standard in pollution control. Therefore, significant proportion of the equipment needs to be manufactured and imported from UK to Kochi.

- Very Low Emission

- High Efficiency

- Less water intake

- Can handle all types of MSW

- Reliable and robust

- Minimal maintenance

- Meets global requirements for green energy generation

Environmental Benefits

- Reduces fossil fuel dependency by generating electricity from Waste.

- Combusting one ton of MSW reduces oil use by one barrel (i.e., 35 gallons) or 0.25 tons of high heating value coal.

- Comparatively lower carbon emissions.

- Do not have the aqueous emissions that may be experienced in landfills, either now or in the distant future.

- Reduce the space required for land filling by about 90% (one square foot per ton of MSW).